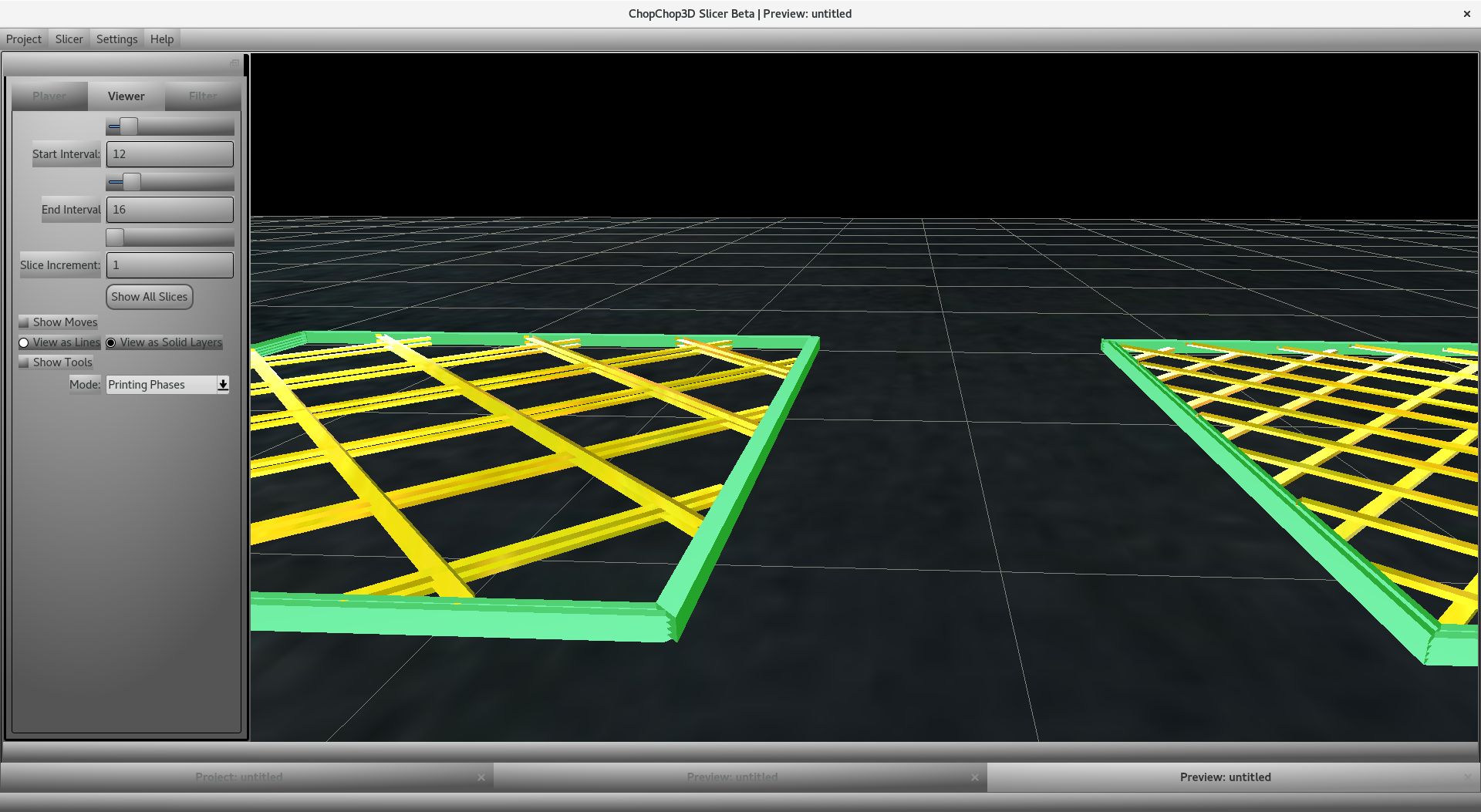

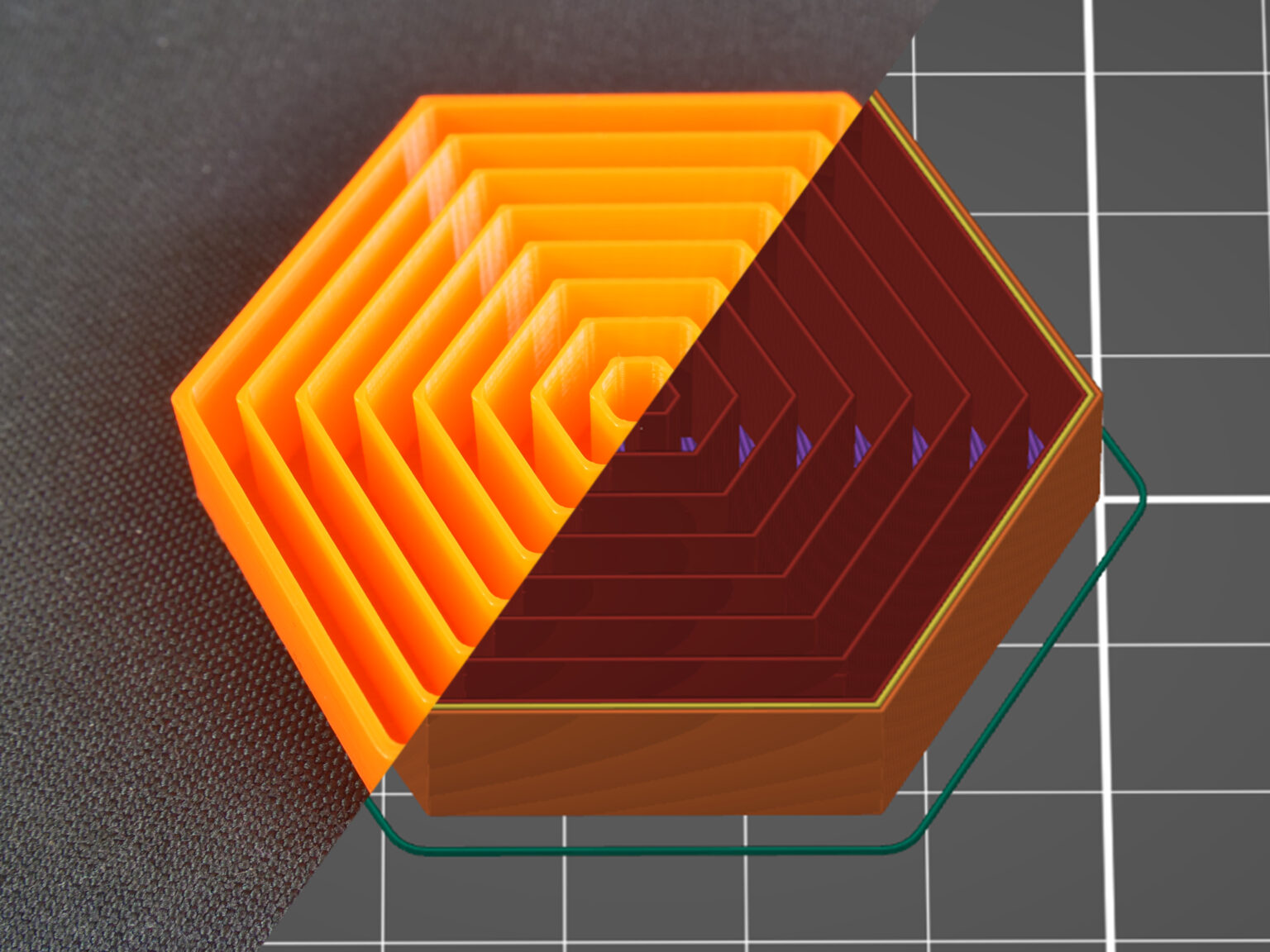

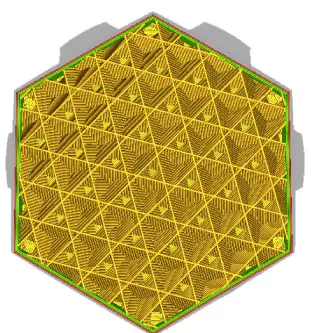

Knowing that a hexagonal structure uses the least material to create a lattice of cells within a given volume, we let our design take inspiration from the way that bee’s nests intersect two opposing honeycomb layers into each other. Experiment and enter in what tends to work for you (50-75% of the layer height seems to work well). A friend and I recognized the limits of current infill patterns and decided to design our own. After all, we’re talking about the internal supporting structure of a part, concealed and caged by the solid and smooth outer walls, only visible during the printing process. Default values of 0.2 and 0 are pre-filled for convenience, although the appropriate support contact Z will differ with layer height and your printer's capabilities. JTom Bardwell Guides, 3D Printing Guides It’d be easy to pass off infill patterns as yet another setting amid the sea of tweakable options in your favorite slicer. This box is a dropdown box that is also editable.

Its very difficult to become overwhelmed with slic3r as apposed to Prusa, Cura, and Super Slicer. I usually use honeycomb, as it is very strong even with a low fill density, but any of the others work just as well. The contact Z distance is the amount of space between the lowest level of support and the underside of the model/layer being supported. The next thing to set is the infill pattern.

#Super slicer infill patterns how to

In this episode I talk about how to insert a color ch. Therefore the Enforce support option will cause support structures to be printed for the given number of layers, regardless of the angle threshold value. Welcome to 365Prints where I talk about 3D printing, 3D design and specifically the CR6-SE 3D printer.

Small models, and those with small footprints, can sometimes break or detach from the bed. Support generation is a relatively complex topic, and there are several aspects which determine the optimal support, it is strongly recommended to set the threshold to zero and allow Slic3r to determine the support required. One uses more filament the other slows your print time down. To be honest though if you are worried about shaking your rig apart you could try slowing the print speed down when printing the infill for these types of prints. Providing a value of zero to the Overhang threshold parameter tells Slic3r to detect places to provide support automatically, otherwise the degrees given will be used. This will force the slicer to make smaller areas solid versus using your infill pattern to fill the area. The first thing to do is activate the support material option by checking the Generate support material box.

0 kommentar(er)

0 kommentar(er)